Hotest Articles

How China’s manufacturing and rapid prototyping services are adapting and leading Industry 4.0

Part I: The evolution of China’s manufacturing industry

It is common knowledge that China is the world’s largest manufacturing nation. In recent years, roughly 40% of the country’s Gross Domestic Product (GDP) has come from the manufacturing sector. What is perhaps less common knowledge is that China’s manufacturing industry is undergoing a significant transformation in a bid to keep on top of global manufacturing demands and evolving manufacturing technologies and trends.

Though it was perhaps once known for the mass production of low value goods, China is revamping its manufacturing sector, transitioning to the production of high value goods and services. Driving this drastic industrial change is the Made in China 2025 initiative, which launched in 2015.

Made In China 2025 focuses on high value industries like:

Aerospace

Automotive

Robotics

Electronics

Pharmaceutical

Made In China 2025 is a strategic roadmap with the goal of evolving and modernizing China’s manufacturing sector using new state-of-the-art processes like digital manufacturing, rapid prototyping, CNC machining and Industry 4.0 technologies. Made in China 2025 is also shifting the focus away from low value goods to high value industries like the automotive, aerospace, electronics and robotics sectors, among others.

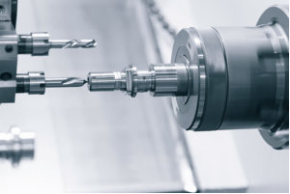

In this changing manufacturing landscape, CNC machining is becoming established as a key production process for many industries, both in China and the world. CNC machining’s high degree of automation and accuracy, as well as its versatility and material compatibility, are leading to unlimited applications in industrial machinery, transportation equipment, electrical and electronic goods.

To meet this growing demand for advanced manufacturing and CNC machining services, China is seeing the emergence of a profitable new business area: CNC manufacturing networks and streamlined manufacturing service bureaus.

Part II: Growth of CNC machining services in China

Though CNC machine shops and rapid prototyping services are not a new phenomenon, we are experiencing an overhaul in how these services operate. The days of clients waiting several days or weeks for a quote and lead time estimate are going the way of the dinosaur as a new, digitally powered era is being ushered in.

Digital trends that are taking hold around the world are having a significant impact on the manufacturing industry and how it conducts business. Advanced design software and generative design tools are changing how products and parts are conceived and designed, while digital inventories and logistics programs are streamlining how companies store and ship their products.

On the level of CNC machining services in China, we are seeing the most drastic changes in the ordering process. Intelligent algorithms power online ordering engines, such as RapidDirect’s leading platform, enabling customers to receive instant quotes and lead time estimates for their prototyping or production jobs.

Advanced manufacturing technologies and digital innovations are heralding a new age for manufacturing services, and China has experienced a recent boom in online ordering platforms for CNC machining, additive manufacturing, sheet metal fabrication and injection molding.

Today, several rapid prototyping services and production service bureaus exist in China.

Part III: Rapid Prototyping reaching new heights

While we touched on this briefly in the previous section, we really want to emphasize the dramatic effect that online ordering platforms, like RapidDirect’s service, are having on rapid prototyping and production workflows.

Thanks to intelligent algorithms informed by the extensive experience of industrial engineers, we have sped up the manufacturing cycle without sacrificing or compromising quality. Online quoting engines enable customers to receive instant quotes for their prototypes or parts as well as lead time estimates.

Part IV: Serving China and the world

Though China’s intelligent rapid prototyping services do have a local market, many are looking abroad to serve the manufacturing and prototyping needs of the global market. We at GUAN SHENG work with clients from all over the world, including Emirate, Benz, NASA, Nikon, Emerson, Toyota, HP, who benefit from our rapid turnaround times and competitive production rates.

In general, working with an external CNC machining service provider can offer customers many benefits. For one, state-of-the-art CNC machining equipment is expensive, meaning that many small or medium-sized businesses (SMEs) cannot afford the investment of owning their own machine, especially for prototyping. Second, CNC machining requires an experienced operator with specialized training. This means that companies working with in-house CNC machining must invest in the personnel and adequate training, which can also be costly.

By working with external CNC services, businesses can make the most of the technology and can benefit from the expertise of CNC shop operators, without having to make a significant investment in CNC machining equipment and operators.

Why Western companies are working with Chinese rapid prototyping services:

Low raw material costs

Lower labour costs

Thinner profit margins

Sophisticated logistics

Easy communication

There are several other factors that make working with a CNC machining service in China even more beneficial to customers from around the world. Cost, of course, is the primary motivator for selecting a rapid prototyping service in China. The reasonable rates that services like RapidDirect are able to offer are due to a few factors. First, raw material costs are lower in China than in Western countries, because the country is a leader in raw material extraction and production. Other factors, like lower labor costs and thinner profit margins also lead to a more competitive service cost for customers.

Online quoting engines and digital advances have also broken down communications barriers between Chinese rapid prototyping services and Western companies, not only creating more trust between the two but also making it easier than ever to keep track of orders and CNC manufacturing progress. Finally, state-of-the-art logistics and shipping enable prototypes and machined parts to be shipped and delivered to customers around the globe with unprecedented speed.

Part V: Working with GUAN SHENG

GUAN SHENG’s smart online quoting engine and extensive manufacturing network make us stand out within the CNC machining services market. Our entire platform—from ordering to part delivery—is geared towards making the customer experience as simple and efficient as possible. Our platform has made us the prototyping service of choice for customers in the aerospace, automotive, medical, robotics and consumer goods industries, among others.

Part VI: Addressing industry pain points with manufacturing network

Having been an active provider of rapid prototyping and low-volume manufacturing services since 2009, GUAN SHENG understands the pain points of the manufacturing industry. Thanks to our experience working with customers from across many segments and from around the world, we have refined our process to address issues that often come up when working with traditional manufacturing services.

Industry pain points:

Inappropriate solutions and suppliers

Inefficient communication

Indefinite pricing

Invisible production process

Unpredictable lead times

First, we understand how challenging it can be for a customer to find appropriate solutions and suppliers for their rapid prototyping or small-batch production needs. Our service overcomes this challenge with a user-friendly online platform that clearly indicates our services, capabilities and strengths. Before even ordering parts from us, you’ll have a clear idea what it is like to work with us.

The second pain point we have tackled with our online CNC machining service is inefficient communication. Up until recently, customers looking for a rapid prototyping service were plagued by time-consuming price and lead time negotiations. Often, to receive a competitive quote, clients would have to contact several different suppliers, resulting in a lengthy search process. Now, thanks to intelligent quoting software and easy-to-use online platforms, businesses can receive quotes rapidly and without much effort.

Part VII: The RapidDirect Manufacturing Network

As we’ve illustrated, GUAN SHENG is not just a user-friendly web interface. While our online platform connects us to clients across the world, there is a lot going on behind the scenes as well. For one, GUAN SHENG operates a factory in XIAMEN, China, one of the world’s most prominent high-tech hubs. There, our team of highly trained technicians, machinists and engineers work to transform our customers’ digital files into high-quality parts.

Beyond that, GUAN SHENG also brings together manufacturers from across the country, forming the largest manufacturing network in China. Today, our manufacturing network comprises over 50 manufacturing partners, each of which has undergone a strict assessment and evaluation to become a qualified member of our network.

With all these manufacturers at our disposal, GUAN SHENG has the means to take on numerous clients at once, without adding to lead times and costs. In other words, when our in-house manufacturing is at capacity, we can select the best candidate from our manufacturing network to take on a new job, without asking clients to suffer through extended wait times.

Moreover, if a client wants to manufacture a part that requires a manufacturing process, material or specification that GUAN SHENG cannot provide through its in-house service, we can find the right manufacturing partner to complete the project.

Part VIII: Other services

In addition to CNC machining services, GUAN SHENG also provides a number of other rapid prototyping and low-volume manufacturing services, including injection molding, sheet metal fabrication and 3D printing. Our customers are welcome to visit the RapidDirect website to peruse our entire offering.

Our injection molding services include a range of processes, including thermoplastic injection molding, mold making, overmolding and insert molding. These processes, in combination with a broad range of injection molding materials such as rigid, flexible and rubber plastics, enable us to undertake rapid prototyping and low-volume manufacturing jobs for a wide range of industries and applications.

Turning to sheet metal fabrication, GUAN SHENG and its extended manufacturing network have the tools to cut, stamp or weld many types of metal, including steel, aluminum and copper alloys. Our sheet metal fabrication services are versatile in terms of applications, but are commonly employed for the production of enclosures, brackets and chassis structures.

Last but not least, our 3D printing services are opening up new opportunities for rapid prototyping and small-batch production. Because of the design freedom associated with 3D printing (also known as additive manufacturing), we can help our customers to build parts with increasingly complex geometries. Today, we offer three key 3D printing technologies through our services: Fused Deposition Modeling (FDM), which uses a hot end to extrude plastic filaments; PolyJet 3D printing, a multi-material and multi-color 3D printing technique; and Selective Laser Sintering (SLS), a powder-based process that produces highly accurate, high-quality parts.

To complement our CNC machining, injection molding, sheet metal fabrication and 3D printing services, GUAN SHENG also offers a comprehensive finishing solutions portfolio. Customers can choose from a wide selection of finishing processes to ensure that their products meet their exact specifications.

FAQ

Q: What is the Made in China 2025 initiative?

A: Made in China 2025 is a strategic roadmap set out by the Chinese government that has the goal of modernizing China’s manufacturing sector using new state-of-the-art processes like digital manufacturing, rapid prototyping, CNC machining and Industry 4.0 technologies. Made in China 2025 also seeks to focus on new high-value markets like aerospace, robotics and automotive.

Q: What is an online quote engine?

A: For our CNC machining service, our online quote engine is a web-based platform powered by intelligent algorithms. Based on customer input, these algorithms automatically generate a price quote that reflects the part design, chosen material and specifications. GUAN SHENG ’s quote engine also provides customers with an estimated lead time.

Q: What manufacturing services does RapidDirect offer?

GUAN SHENG is a manufacturing service that specializes in rapid prototyping and small-batch production. Our manufacturing capabilities include CNC machining, injection molding, sheet metal fabrication and 3D printing. In addition to these manufacturing processes, we also offer a broad selection of finishing solutions.