Hotest Articles

A look at what influences the cost of CNC machining metals and what the most cost-effective options are.

Close-up frontal view of ready to work CNC milling machine with moving table

Close-up frontal view of ready to work CNC milling machine with moving table

When it comes to the cost of CNC machining, there are a number of factors that need to be taken into consideration. For instance, in a previous blog post, we looked at how part design can influence the cost of CNC machining. Today, we’ll look at how material choice, and specifically metals, can have an impact on the price of machining.

Metals suitable for CNC machining are each distinguished by different mechanical properties—like strength, ductility, corrosion-resistance, and others. These properties result in a range of machinability factors, meaning that some materials (with good machinability) are easier to mill and machine than others.

Generally, the easier the material is to be machined, the cheaper it is to work with. This is because highly machinable metals can be processed more quickly, which drives down CNC costs. However, the cost of raw materials must also be taken into account, as it can affect the overall cost of machining.

At GUAN SHENG, we offer a comprehensive metal material selection for CNC machining, including many of the most popular CNC materials and more specialized options. Our range of available materials, which can be consulted in full here, covers various applications. Below, we’ll take a look at the most cost-effective metals to the CNC machine.

1. Aluminum

Available in a range of different alloys, Aluminum is one of the most cost-effective metals to CNC machine. With a high machinability factor (varying slightly depending on the alloy) and a low raw material cost, it is no wonder that Aluminum is one of the most popular metals in the CNC machining world. With a high strength-to-weight ratio and good corrosion and temperature resistance, Aluminum is used by a range of industries, including aerospace, automotive, healthcare, consumer goods and more. At GUAN SHENG, we offer a range of Aluminum alloys for CNC machining, including the popular Aluminum 6061-T6, as well as Aluminum 7075-T6 and Aluminum 6082.

2. Stainless Steel

Stainless steel—also available in a range of alloys—is a popular and versatile material for CNC machining applications. Though not as machinable as Aluminum, Stainless Steel does maintain a good machinability-to-low-raw-material-cost ratio. Stainless Steel boasts a number of properties—including high strength, chemical resistance, and hardness—that make it ideal for applications in the automotive, aerospace, food, marine and healthcare industries, to name a few. GUAN SHENG offers a selection of Stainless Steel alloys for CNC Machining: 303 Stainless Steel, which has good machinability and is ideal for producing fittings and fasteners; 304 Stainless Steel which is commonly used for cookware and chemical-processing equipment; and 316 Stainless Steel, which is suitable for more extreme applications such as those in the marine or chemical industries. Out of the three, 303 Stainless Steel is the most cost-effective option because of the presence of sulphur and phosphorus.

3. Brass

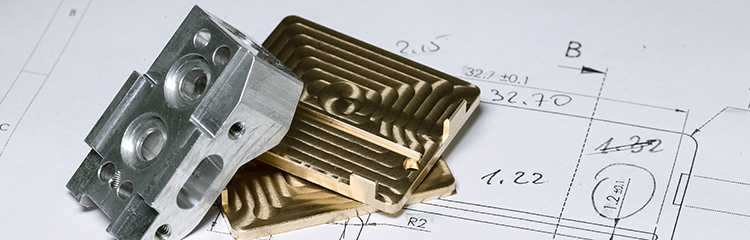

Brass Next on the list of cost-effective CNC Machining metals is Brass, a metal alloy made of a combination of copper and zinc. Brass has a high machinability factor (better than Stainless Steel), though its raw material cost is slightly higher. However, Brass has a high scrap return, which can reduce the cost of raw material. GUAN SHENG offers two Brass alloys: Brass C360 and Brass C260, which has a higher zinc content. Brass C360 is the most cost-effective option for machining Brass, because of its soft, easily machinable nature and the low impact it has on machining tools. In general, Brass is known for its medium hardness and high tensile strength, making it suitable for applications in the electrical goods, consumer goods, architecture, automotive and healthcare sectors.

4. Copper

Copper Similar to Brass, Copper has a very high machinability rate, meaning that the metal is itself not expensive to the CNC machine. What drives the cost of Copper up, however, is the price of raw material. Nonetheless, Copper is a popular material for applications that require good electrical and thermal conductivity and is sought after in the automotive, consumer electronics and healthcare sectors. Other material properties include good corrosion resistance. GUAN SHENG offers two Copper alloys for CNC machining: 110 Copper, which has excellent electrical conductivity and formability, and 101 Copper, which has the highest copper content of all the Cu alloys and therefore has the best conductivity.

5. Titanium

Titanium On the higher cost end of CNC machining metals is Titanium. Titanium is notoriously challenging to machine due to its low thermal conductivity and high strength. Moreover, the raw material has a relatively high price, which leads to high material and machining costs. Still, Titanium’s unique properties—including an excellent strength-to-weight ratio—make it a popular material for specialized industries such as aerospace and medical. Titanium is also characterized by excellent corrosion, chemical and temperature resistance. GUAN SHENG customers seeking to work with Titanium can choose from two machinable alloys: Grade 2 Titanium, with high corrosion resistance, and Grade 5 Titanium (Ti6Al4V), the strongest Titanium alloy.